our technology

Energen™ utilizes in-house developed hydrogen-on-demand technology to improve diesel engine combustion, increasing efficiency while reducing fuel consumption and emissions.

Hydrogen and Oxygen Generation

At the core of Energen™ is a PEM electrolyser, which splits distilled water (H₂O) into hydrogen (H₂) and oxygen (O₂) using an electrochemical process. This method is highly efficient, producing only the required amount of hydrogen and oxygen on demand, eliminating the need for high-pressure storage or external gas supplies.

Enriching the Combustion Process

The generated H₂ and O₂ gases are directly introduced into the engine’s air intake system. This results in an optimized air-fuel mixture, leading to faster and more complete combustion. Unlike conventional diesel combustion, which often leaves behind unburned fuel and harmful emissions, hydrogen acts as a combustion enhancer, improving flame propagation and reducing energy losses.

Cleaner, More Efficient Combustion

With hydrogen increasing flame speed and oxygen improving oxidation, the diesel fuel burns more efficiently. This leads to:

- Lower emissions – Reduced particulate matter (PM), nitrogen oxides (NOx), and unburned hydrocarbons.

- Reduced fuel consumption – More complete fuel utilization means less diesel is needed for the same power output.

- Enhanced engine performance – Improved torque, smoother operation, and a cleaner combustion chamber over time.

Why It Works

- Faster and more complete combustion – Hydrogen has a high flame speed and combusts more readily than diesel, ensuring more complete fuel burn and reducing unburned hydrocarbons.

- Higher thermal efficiency – Hydrogen’s combustion releases more energy with less fuel input, meaning less diesel is needed to produce the same power output.

- Reduced soot formation – With more complete combustion, fewer carbon particles are left unburned, leading to lower particulate matter and soot emissions. leads to lower maintenance costs and extended engine life.

- Lower NOx formation – Hydrogen-enriched combustion can occur at lower temperatures, reducing the formation of nitrogen oxides (NOx), a major pollutant.

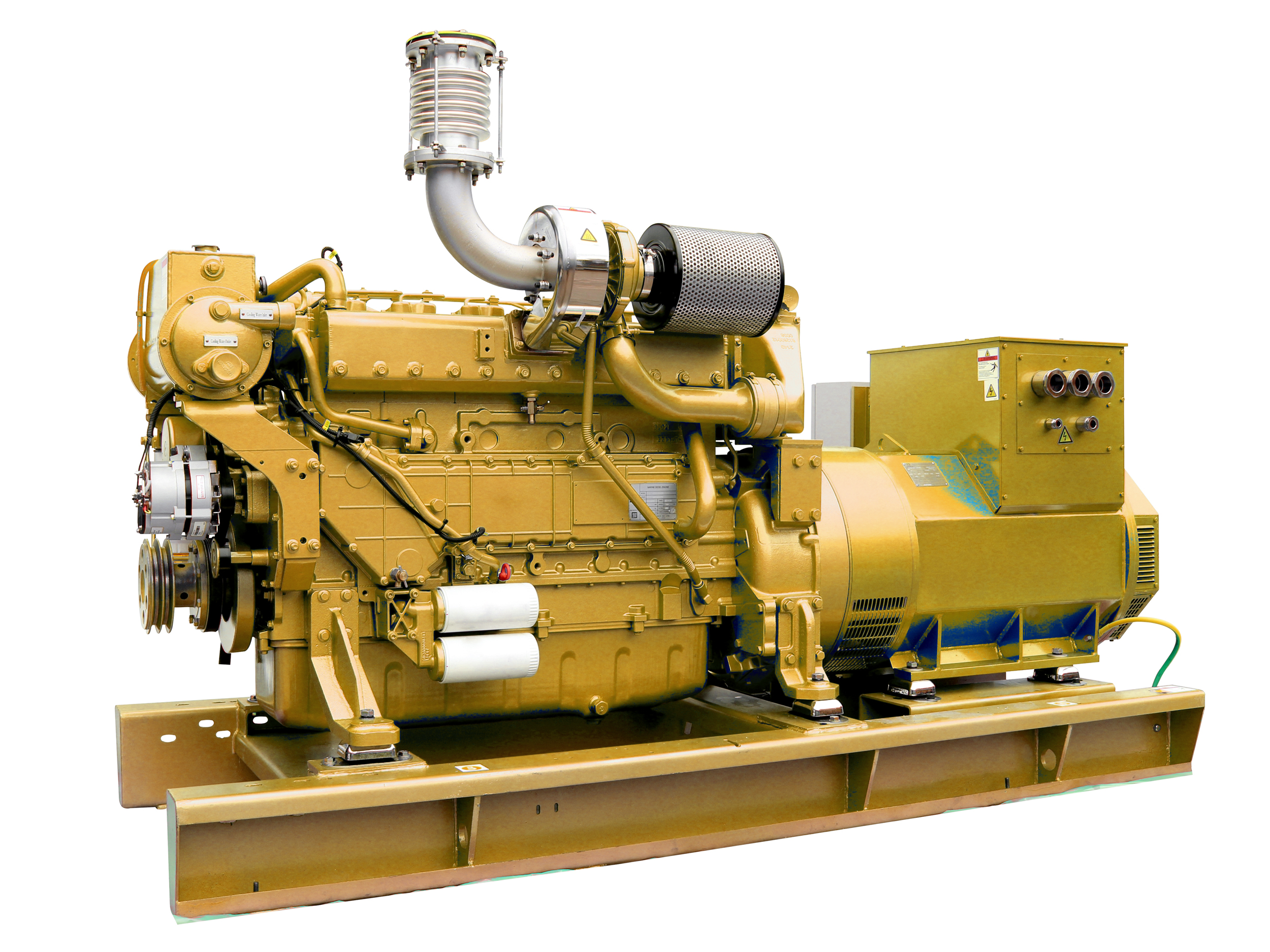

Energen™ seamlessly integrates with existing diesel engines across industries, from marine vessels and construction equipment to backup generators and transportation fleets—delivering a cleaner, more cost-effective energy solution.

Energen™ – Different Size Models

Energen™ is designed to enhance the efficiency of a wide range of diesel engines, from smaller industrial applications to large-scale power generation and marine operations. Our system can be configured to match different engine size and fuel demands.

With it’s modular design, Energen™ can be tailored to meet the needs of various engine applications, ensuring optimized performance and reduced emissions at different scale.

Single-Cell Units

Suitable for engines up to 15 litres, ideal for smaller generators, construction equipment, and vehicles.

Single to Double-Cell Units

Designed for 30–60 litres engines, commonly used in heavy machinery, marine vessels, and larger power generators.

Multi-Cell Units

Engineered for 60–100+ litres engines, providing efficient fuel optimization for large marine vessels, rigs, and industrial power systems.

Energen™ – Operation & Safety

- No Interference with Engine Control Systems – Energen operates independently and does not affect the engine’s electronic controls.

- Automatic Safety Shutdown – Hydrogen production is active only when the engine is running. In the event of a system failure, hydrogen generation stops, and the engine continues to operate normally.

- On-Demand Hydrogen Production – No storage required; hydrogen and oxygen are generated as needed.

- Chemical-Free Operation – Uses only distilled water, with no additional chemicals.

- Comprehensive Sensor Monitoring – Equipped with temperature sensors, pressure sensors, water level sensors, and electrical monitoring to ensure safe and efficient operation. A pressure sensor prevents gas buildup, and oil pressure from the engine is also monitored for added safety.

- Remote Monitoring & Control – System performance can be tracked and managed remotely.

- Data Logging – Continuous database recording for performance analysis and system diagnostics.

Energen™ – Installation

Energen™ is designed for easy integration with diesel engines across various applications. The system operates using 24V power, typically sourced directly from the engine, with a maximum draw of 40 amps. Alternatively, it can be powered from the electrical grid if available.

Key Installation Features:

- H₂ and O₂ Supply – The generated hydrogen and oxygen are delivered via hoses connected directly to the engine’s air intake, ensuring seamless combustion enhancement.

- Engine Monitoring – Two independent oil pressure sensors are installed on the engine to detect when it is running. These sensors provide critical input to Energen’s control system, automatically starting and stopping hydrogen production as needed.

- Optional Diesel Flow Meter – For real-time fuel consumption tracking, a diesel flow meter can be installed and integrated with Energen’s system for continuous logging and efficiency analysis.

With minimal modifications required, Energen™ provides a straightforward and reliable installation process, making it a flexible solution for a wide range of diesel-powered applications.

24/7 Support:

t: +47 51 31 43 00

e: support@energen.no

Contact:

t: +47 51 31 43 00

e: post@energen.no

Management:

Stian Steinsholm, CEO

m: +47 98 29 66 43

e: stian.steinsholm@energen.no